The gradual accumulation of air in a concentric reducer could result in a large bubble that could eventually cause the pump to stall or cause cavitation when drawn into the pump. Eccentric reducer is typically installed at the centrifugal process pump suction.

Why To Use Eccentric Reducers In Pump Suction Piping Enggcyclopedia

And a small discharge nozzle continues into a larger outlet pipe via an expander.

. It is the sloping quality of the reducer that has the potential for an air pocket to form if used on the suction side and oriented with the sloping side facing up. When liquids are pumped that carry a small fraction of a heavier and immissible liquid the practice is to put in an eccentric reducer with the flat side on the bottom. Why eccentric reducer is located on pump suction side.

The other application of an eccentric reducer is to increase the line size to 4 for thermowell temperature gauge installation. If concentric reducer are used their upper. Air pockets may form if concentric reducer is used at pump suction which.

Its the pump SUCTION that needs to be an eccentric reducer that is always flat on top FOT The eccentric reducer on the pump suction. Eccentric Reducers For Pump Suction - posted in Industrial Professionals. Results in Cavitation and cause damage to Pump.

In the past the theory was that pump suction reducer should be eccentric flat on top. Eccentric reducers are used at the suction side of pumps to ensure air does not accumulate in the pipe. This configuration prevents air pocket accumulation at the upstream end of the reducer.

Eccentric reducers are used at the suction side of pumps to ensure that air does not accumulate in the pipe. How can you calculate line loses in the suction pipe if the liquid is forced through only part of the pipe because the rest of the pipe is occupied by a large air pocket. That ensures that when drops of the heavier liquid come along the bottom of the line they too pass immediately and unhindered through the pump.

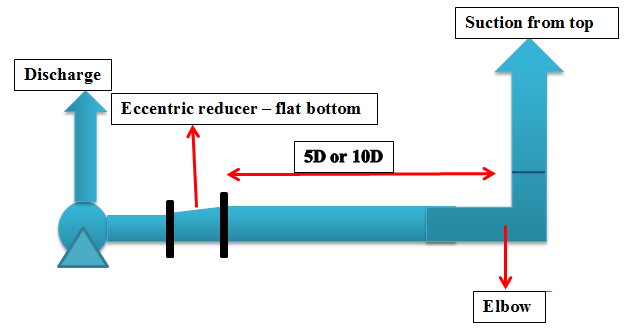

Eccentric reducers are used at the suction side of pumps to ensure air does not accumulate in the pipe. An eccentric reducer is used upstream of pumps to increase the fluid velocity and provide a net positive suction head. Eccentric reducer is typically installed at the centrifugal process pump suction nozzles in order to facilitate proper transition from the the larger diameter low flow velocity moderate friction loss suction piping to the pump suction nozzle.

Using eccentric reducers on the horizontal run of suction piping is technical and very important in most all pump installations. Eccentric reducer in pump section pipeing minimized accumulation of any air or gas bubbles in the suction. Concentric reducer is recommended for vertical inlet suction piping or horizontal installations where there is no potential for air vapor accumulation.

Which face material of seal is used for chemical transfer pump. Designer has to pay attention to the proper installation of eccentric reducers at the suction piping of pumps. Answer 1 of 4.

To avoid this problem Eccentric Reducer with Flat Side Up FSU is used in Pump Suction. An air pocket at the pump suction and allow air gas or vapors to be evacuated. Why need an eccentric reducer.

Replying to Gary Lagnese 11182020 105120 am Could not a concentric then be used Concentric reducers are only permitted on the discharge side of the pump. For example -- 6 suction pipe from tank going to 3 suction flange on pumpWhen eccentric 3 is on top of 6 suction there is a greater tendency to pull entrained gas. Eccentric reducers are used in pump suction nozzle to inhibit cavitation at the impellers and provide the necessary size reduction.

A reducer is also installed upstream and downstream of pressure safety valves PSVs in flare lines. Eccentric reducer is recommended for horizontal flow to the pump. Put the flat on top when the fluid is coming from below or straight and the flat on the bottom when the fluid is coming from the top.

The gradual accumulation of air in a concentric reducer could result in a large bubble that could eventually cause the pump to. In a concentric reducer air gradually accumulates and form a large bubble that could eventually cause the pump to stall or. Click to see full answer.

Always use an eccentric reducer at the pump suction when a pipe size transition is. The arrangement also leaves significant liquid level which can not be pumpedWhen eccentric 3 is on bottom of 6 suction. The primary reason for using reducer and expander in inlet outlet piping is to join the respective pipe sizes with smaller pump nozzles.

Larger upstream pipe on the suction side joins with a smaller suction nozzle using a reducer. Matching the pipe size with pump nozzles.

Why To Use Eccentric Reducers In Pump Suction Piping Enggcyclopedia

Pumps Suction Piping Eccentric Reducers Straight Lengths The Process Piping

Review And Optimisation Of Pump Suction Reducer Selection Semantic Scholar

0 Comments